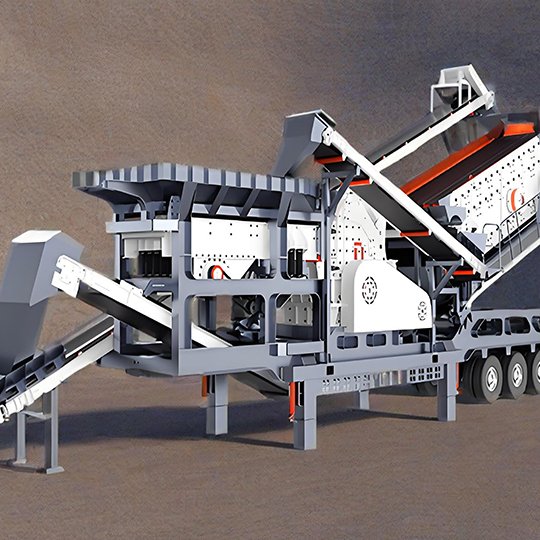

Semi-Mobile Crusher and Screen

Sandreck Semi-Mobile Crusher and Screen is developed on the basis of mobile crusher, which only needs the ground to be leveled to assemble the production line.

- Modular design

- Only simple foundation is needed

- Including coarse, medium and fine crushing, shaping, sand making, screening and other functions

What Is Semi-Mobile Crusher and Screen?

The Semi-Mobile Crusher and Screen produced by Sandreck is a modular mobile crushing and screening equipment developed by our factory to meet the needs of users for large crushers. Sandreck Semi-Mobile Crusher and Screen combines the advantages of long service life of fixed production line and flexible transfer of mobile crushing station. It adopts independent frame support and can be produced as long as the chassis is placed horizontally.

The Semi-Mobile Crusher and Screen sold by Sandreck occupies a small space and is easy to hoist and transport. It is very suitable for crushing and screening projects that require fast on-site installation and tight construction period.

Semi-Mobile Crusher and Screen Advantages

It meets the large production capacity requirements of mobile production lines, with diverse combinations.

Professional equipment supplier, the semi-mobile crusher and screen sold in the factory is affordable.

No infrastructure is required, our equipment can be quickly assembled and put into production within 72 hours.

Our equipment has hydraulic control system, with one-button start and stop function, simple operation.

Our equipment has sufficient platform space, convenient on-site inspection and maintenance.

It adopts a fully automatic lubrication system, eliminating the trouble of frequent manual refueling.

Semi-Mobile Crushers and Screens Applications

Sandreck Semi-Mobile Crusher and Screen are usually higher in processing capacity than mobile types (100-2000 t/h) for medium and high hardness materials (such as ore and hard rock), and can be configured with multi-stage crushing.

Semi-Mobile Crusher And Screen Adopts Integrated Control System

Sandreck Semi-Mobile Crusher and Screen adopts an integrated control system. Our machine adopts an integrated control system, with a simple and clear touch screen interface, remote control, and a one-button start and stop function. Just press a button to start or stop each module to ensure safe.

Company Advantage

Sandreck is a Semi-Mobile Crusher and Screen Manufacturing Company integrating R&D and design, production and sales. It possesses over 100 sets of machining equipment of various specifications, including CNC vertical lathes, deep hole drills, laser cutting machines, planers, CNC lathes, CNC boring and milling machines, etc.

We are a Mining machinery corporation. Our Semi-Mobile Crusher and Screen Plant are used by customers all over the world because we will tailor professional solutions and mature supporting design plans for you based on your needs, creating the greatest value for you.

Golden Service

For your Semi-Mobile Crusher and Screen equipments, we stand by your side 24 hours a day, providing round-the-clock protection for your choices!

We will arrange engineers to conduct actual surveys and scheme designs at your construction site, and provide customized product services according to your needs.

Our production process is clear and transparent, strictly controlled by professional quality inspection, with accurate inventory preparation and timely delivery

We will dispatch engineers go to the site to provide technical training on equipment installation and commissioning, operation, maintenance and other aspects

24-hour customer service response mechanism, providing you with technical services throughout the entire life cycle

Semi-Mobile Crusher and Screen Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: Basalt

Capacity: 100-200 t/h

Finished size: 12 stone, 13 stone, mechanism sand

Processing material: Limestone

Capacity: 300 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 2

Processing material: granite

Capacity: 200 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Processing material: Cobblestone

Capacity: 150-200 t/h

Finished size: 12 stone, 13 stone, mechanism sand

More About Our Company

- Technical Parameters

Standard Model Number | Supporting Equipment Model | Model | Feed Size | Yield(t/h) | Maximum Handling Capacity(t/h) |

| MK70-4 | FK0936 | PEV500X750 | 450 | 40-60 | 50-70 |

| 3SKX1545 | PYB900 | ||||

| MK100-4 | FK0936 | PEV600×900 | 500 | 35-110 | 70-120 |

| 3SKX1560 | HST100H1 | ||||

| MK150-4 | FK0936 | PEV600×900 | 500 | 65-160 | 130-170 |

| 3SKX1560 | HST160H1 | ||||

| MK150-3 | FK1142 | C15X1213M | 550 | 100-170 | 120-190 |

| 3SKX1560 |

The initial installation of Sandreck Semi-Mobile Crusher and Screen takes about 1-3 days (fixed foundation is required), and the subsequent transfer and disassembly takes 1-2 days, which is faster than the fixed type, but slower than the fully mobile type.

Semi-Mobile Crusher and Screen maintenance is not complicated, please contact us for specific maintenance details.

The investment of the two depends on the specific working conditions, and the prices are different.

You can consult the customer service online through the website or whatsapp+13666293477, we will contact you within 24 hours.

Related Product

Efficient screening of sand and gravel aggregates, ore sorting, and coal mines

Equipped with high-performance Impact Crusher and Screening equipment.

Crushing and screening of large reinforced concrete in the concrete recycling industry.