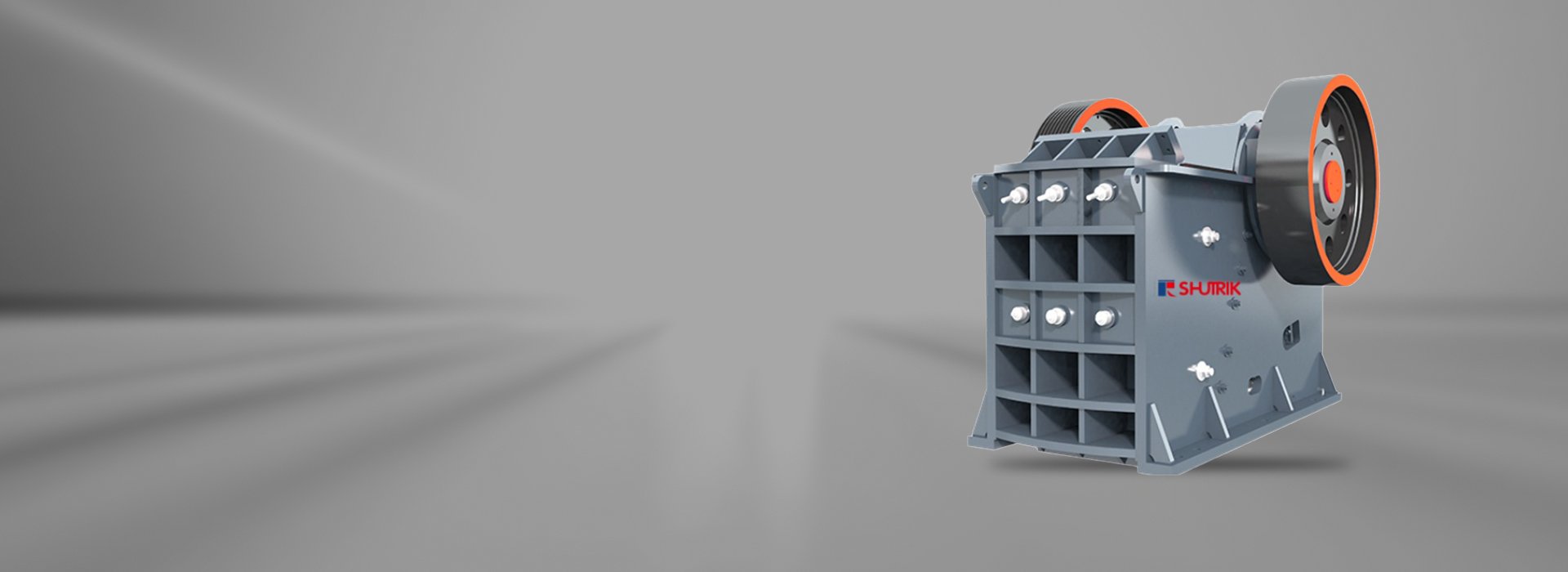

PE Jaw Crusher

Sandreck PE Jaw Crusher is the most widely used primary crushing equipment in the field of mining and quarrying.

- Feed size: ≤1000MM

- Motor power: 15-200KW

- Processing capacity: 5-800T/H

Your Expert PE Jaw Crusher Supplier In China.

Sandreck PE Jaw Crusher is a common crusher that breaks large stones into small pieces. The motor drives the eccentric shaft to drive the movable jaw to swing periodically, forming an extrusion chamber with the fixed jaw to squeeze and crush the material.

The Sandreck PE Jaw Crusher is a heavy duty machine for primary crushing of hard, abrasive materials such as granite, basalt and concrete. It features a durable cast steel frame and high manganese steel jaws to ensure long-lasting performance in mining, construction and recycling applications. Its optimised crushing chamber design improves efficiency and reduces energy consumption while providing high throughput.

The PE series is easy to maintain, with adjustable discharge settings and reliable operation, making it ideal for stationary or mobile plants. Designed for tough conditions, the crusher combines rugged construction with cost-effective productivity, meeting global standards for durability and safety. Ideal for your aggregate production and mineral processing

Sandreck PE Jaw Crusher Advantages

High manganese steel cast jaw plate is reversible, extending service life and saving costs.

The jaw plate is precision machined to ensure strength and rigidity, improves production efficiency.

Based on large-scale domestic applications, it integrates a variety of advanced technologies.

Sandreck PE Jaw Crusher saves 15%~30% energy per unit, and the system saves more than double energy.

Sandreck PE Jaw Crusher is inexpensive and has low energy consumption, saving you costs.

Unique lubrication system, safe and reliable, easy replacement of parts, and small maintenance workload.

Why Choose Sandreck PE Jaw Crusher?

Sandreck PE Jaw Crusher can simultaneously process various ores with a compressive strength of no more than 320MPa into medium particle size. It is usually used with cone crusher, impact crusher, sand making machine and other equipment.

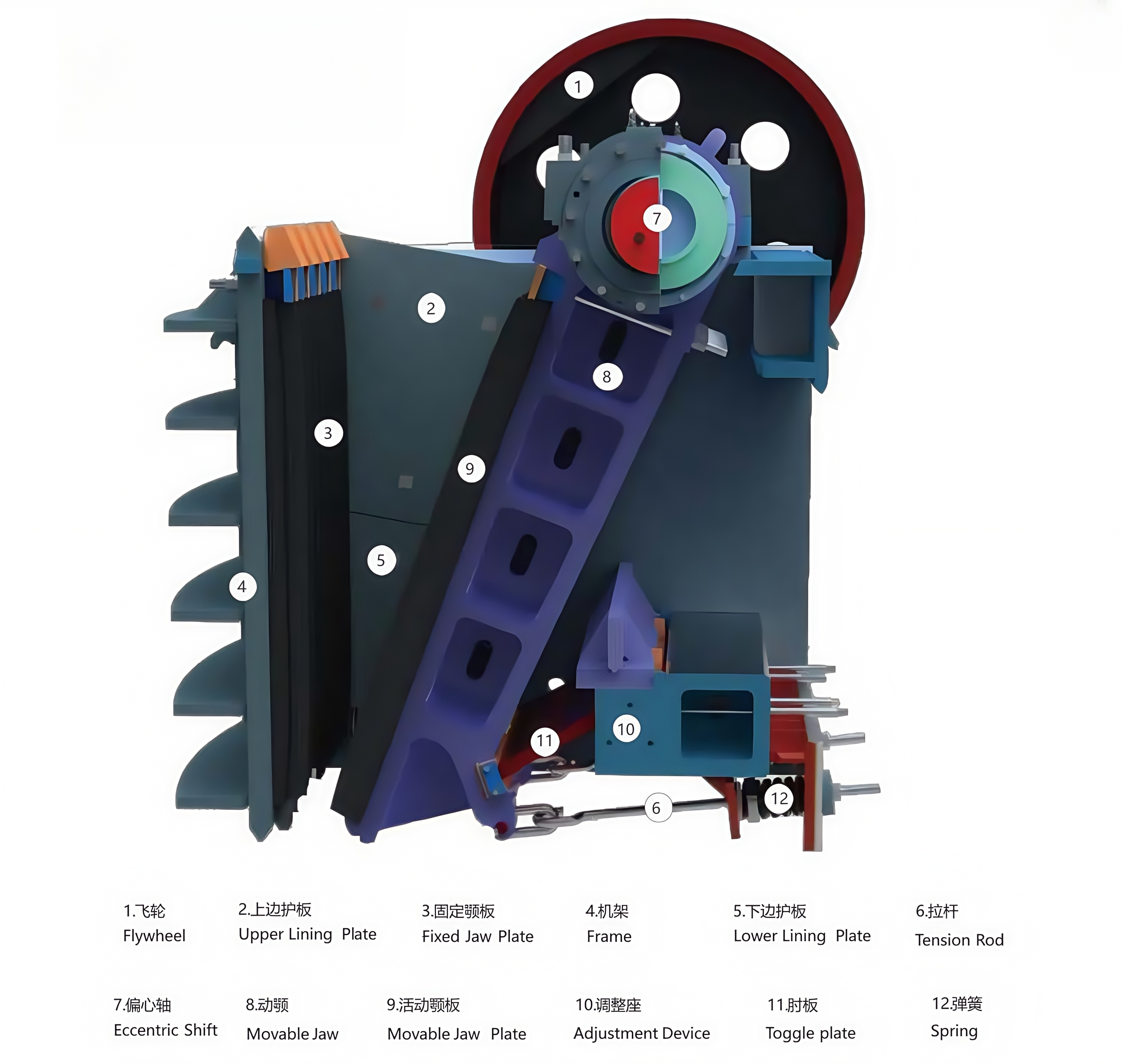

Sandreck PE Jaw Crusher Main Components

Sandreck PE Jaw Crusher mainly consists of Flywheel, Lining Plate (Upper Lining Plate + Lower Lining Plate), Jaw Plate (Fixed Jaw Plate+ Movable Jaw Plate), Frame, Tension Rod, Eccentric Shaft, Adjustment Device, Toggle Plate and Spring, which work together to make PE Jaw Crusher able to complete the material crushing task efficiently.

Company Advantage

Sandreck is a PE Jaw Crusher Manufacturing Company integrating R&D and design, production and sales. It possesses over 100 sets of machining equipment of various specifications, including CNC vertical lathes, deep hole drills, laser cutting machines, planers, CNC lathes, CNC boring and milling machines, etc.

We are a PE Jaw Crusher corporation. Our crushing equipments are used by customers all over the world because we will tailor professional solutions and mature supporting design plans for you based on your needs, creating the greatest value for you.

Golden Service

For your PE Jaw Crusher, we stand by your side 24 hours a day, providing round-the-clock protection for your choices!

We will arrange engineers to conduct actual surveys and scheme designs at your construction site, and provide customized product services according to your needs.

Our production process is clear and transparent, strictly controlled by professional quality inspection, with accurate inventory preparation and timely delivery.

We will dispatch engineers go to the site to provide technical training on equipment installation and commissioning, operation, maintenance and other aspects.

24-hour customer service response mechanism, providing you with technical services throughout the entire life cycle.

PE Jaw Crusher Cases

Sandreck is a well-known Chinese integrated supplier of crushed stone equipment and solutions, and has provided services for over a thousand sand and gravel processing plants.

Processing material: Cobblestone

Capacity: 100 t/h

Finished size: <50mm

Processing material: Quartz

Capacity: 200-400 t/h

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Technical Parameters

- PE Jaw Crusher

| Model | Feed Port Size mm | Maximum Feed Side Length mm | Discharge Port Size mm | Processing Power t/h | Motor Power kw | Dimensions mm |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 5.5 | 896x745x935 |

| PE-150×750 | 150×750 | 125 | 18-48 | 5-16 | 15 | 1200x1500x1200 |

| PE-250X400 | 250×400 | 200 | 20-50 | 5-20 | 15 | 1430x1310x1340 |

| PE-250×750 | 250×750 | 210 | 25-60 | 15-30 | 22-30 | 1667x1545x1020 |

| PE-250X1000 | 250×1000 | 210 | 25-60 | 15-50 | 30-37 | 1695x1921x1440 |

| PE-250×1200 | 250×1200 | 210 | 25-60 | 20-60 | 37-45 | 2192x1900x1950 |

| PE-400×600 | 400×600 | 350 | 40-100 | 15-60 | 30-37 | 1700x1732x1653 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 45-55 | 1950x1878x1855 |

| PE-600×900 | 600×900 | 480 | 65-160 | 90-180 | 55-75 | 2200x2008x1855 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 90-110 | 2624x2302x3110 |

| PE-900×1200 | 900×1200 | 750 | 95-180 | 220-450 | 132 | 3550x2823x3196 |

| PE-1000×1200 | 1000×1200 | 850 | 95-190 | 230-500 | 160 | 3800x3166x3045 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 220 | 4930x3148x3703 |

| PE-1500×1800 | 1500×1800 | 1200 | 220-350 | 400-1000 | 355 | 5630x3210x4120 |

Testimonials

Sandreck PE Jaw Crusher is suitable for the treatment of hard ores such as iron ore, granite and construction waste.

Before starting the machine, you need to make sure that there is no one near the equipment, pay attention to the uniform feeding during operation, and observe the operating status at any time.

Sandreck PE Jaw Crusher includes frame, jaw plate, eccentric shaft, side guard plate, rotating parts, safety device, adjustment device, etc.

We are a Chinese crusher source factory, each unit is ex-factory price, you can leave a message via WhatsApp (+8613666293477), later we will contact you and offer our PE Jaw Crusher’s prices.

Related Product

Used for grading and screening of minerals, quarries, building materials, etc.

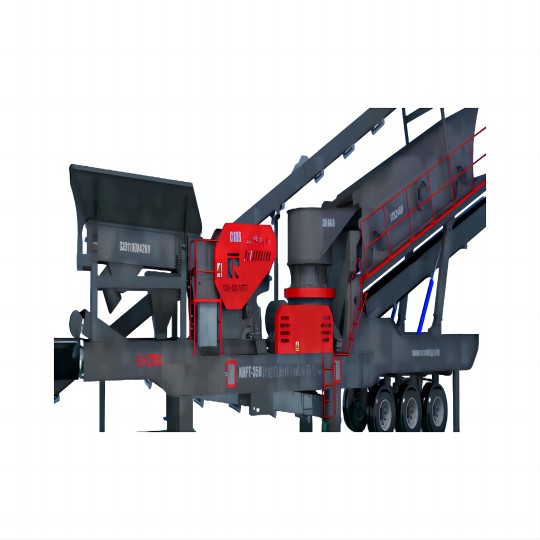

Mobile Crusher Plant’s locomotive traction can be transferred, which is flexible, suitable for multi-site cycle operation.

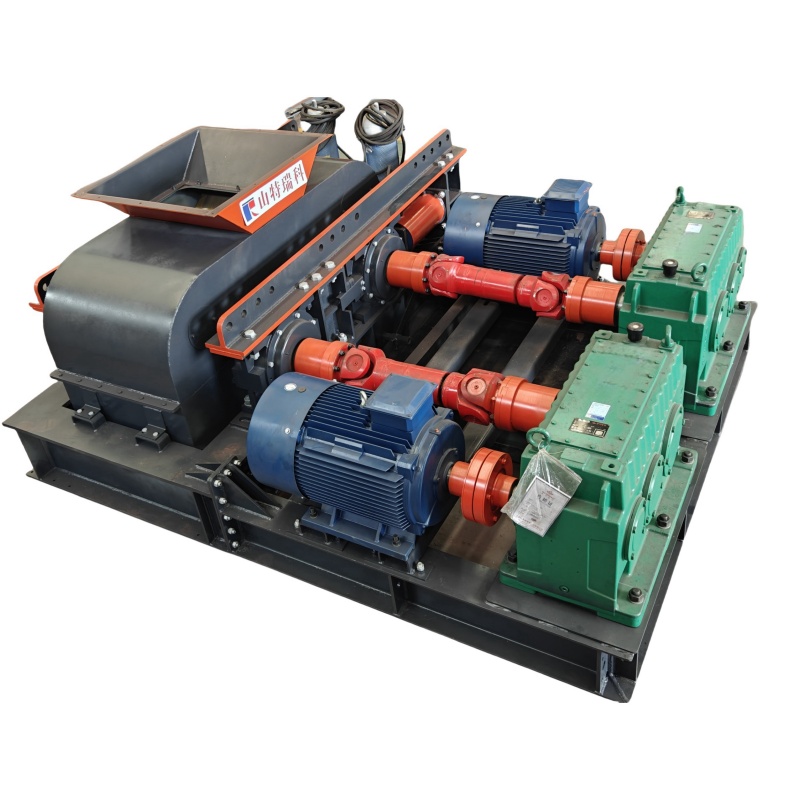

Sandreck Double Roller Crusher is suitable for fine crushing of stones with a finished particle size of 0-5mm.